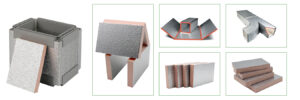

When it comes to modern HVAC ductwork, pre-insulated duct panels are quickly becoming the industry standard — thanks to their outstanding energy efficiency, lightweight structure, and simplified installation. However, choosing the right core insulation material is crucial for ensuring long-term performance and project success. In this article, we compare the three most common types of pre-insulated duct materials: PIR (Polyisocyanurate), PU (Polyurethane), and Phenolic foam.

1. PIR Pre-insulated Duct Panels

Polyisocyanurate (PIR) foam is an advanced version of polyurethane with improved fire performance and thermal resistance. It is widely adopted in commercial HVAC systems due to its balanced performance across multiple factors.

Key Benefits:

- Low thermal conductivity (as low as 0.022 W/m·K)

- Excellent flame retardancy and low smoke emission

- Lightweight and rigid structure

- Long-term thermal stability

Recommended for:

- High-performance HVAC systems in commercial buildings

- Projects with strict fire safety requirements

- Applications requiring long duct runs with minimal energy loss

2. PU Pre-insulated Duct Panels

Polyurethan (PU) is a reliable and cost-effective foam insulation material. While slightly less fire-resistant than PIR, PU still offers excellent insulation properties and is ideal for projects prioritizing budget efficiency.

Key Benefits:

- Efficient insulation with λ values typically around 0.018–0.025 W/m·K

- Lightweight and easy to install

- Cost-effective for large-scale applications

Recommended for:

- Residential HVAC systems

- Budget-sensitive commercial projects

- Systems without stringent fire code restrictions

3. Phenolic Pre-insulated Duct Panels

Phenolic foam is known for its superior fire performance and extremely low smoke emissions, making it ideal for critical environments. It also has the lowest thermal conductivity among the three.

Key Benefits:

- Exceptional fire resistance (often Class 0 or Class A)

- Very low smoke generation

- Outstanding thermal performance (as low as 0.020 W/m·K)

- High compressive strength

Recommended for:

- Hospitals, airports, and cleanrooms

- Government or institutional projects with strict safety codes

- Projects seeking long-term energy efficiency and compliance

- Comparison at a Glance

Comparison at a Glance

| Feature | PIR-Schaum | PU Foam | Phenolic Foam |

| Thermal Conductivity (W/m·K) | ~0.021 | ~0.023 | ~0.018 |

| Fire Performance | Good | Moderate | Excellent |

| Smoke Emission | Low | Moderate | Very Low |

| Weight | Lightweight | Lightweight | Lightweight |

| Cost | Moderate | Lower | Higher |

| Application Scope | Commercial HVAC | Residential & Light Commercial | Critical Facilities |

Which One Should You Choose?

- The right material depends on your project priorities:

- Need high fire safety + long-term efficiency? Choose Phenolic.

- Looking for solid all-around performance? Go with PIR.

- Tight budget with basic requirements? PU might be your best bet.

At GFIDuct, we manufacture and supply high-quality pre-insulated duct panels using PIR, PU, and Phenolic foam, tailored for HVAC contractors, distributors, and engineering firms worldwide. Whether you’re working on a high-rise commercial tower or a compact indoor project, we have the right duct solution for you.

Explore Our Range of Pre-insulated Duct Panels

Visit GFI to view detailed product specifications, project cases, and technical support for:

Need help choosing the right insulation material? Contact our team — we’re here to support your project from design to delivery.